nationwide manufacturing services

product benefits

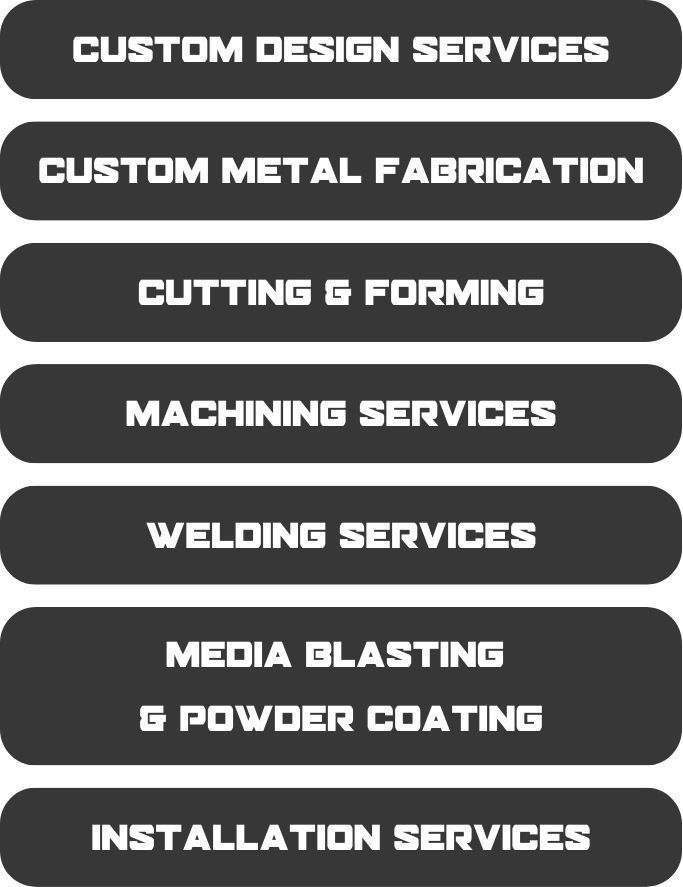

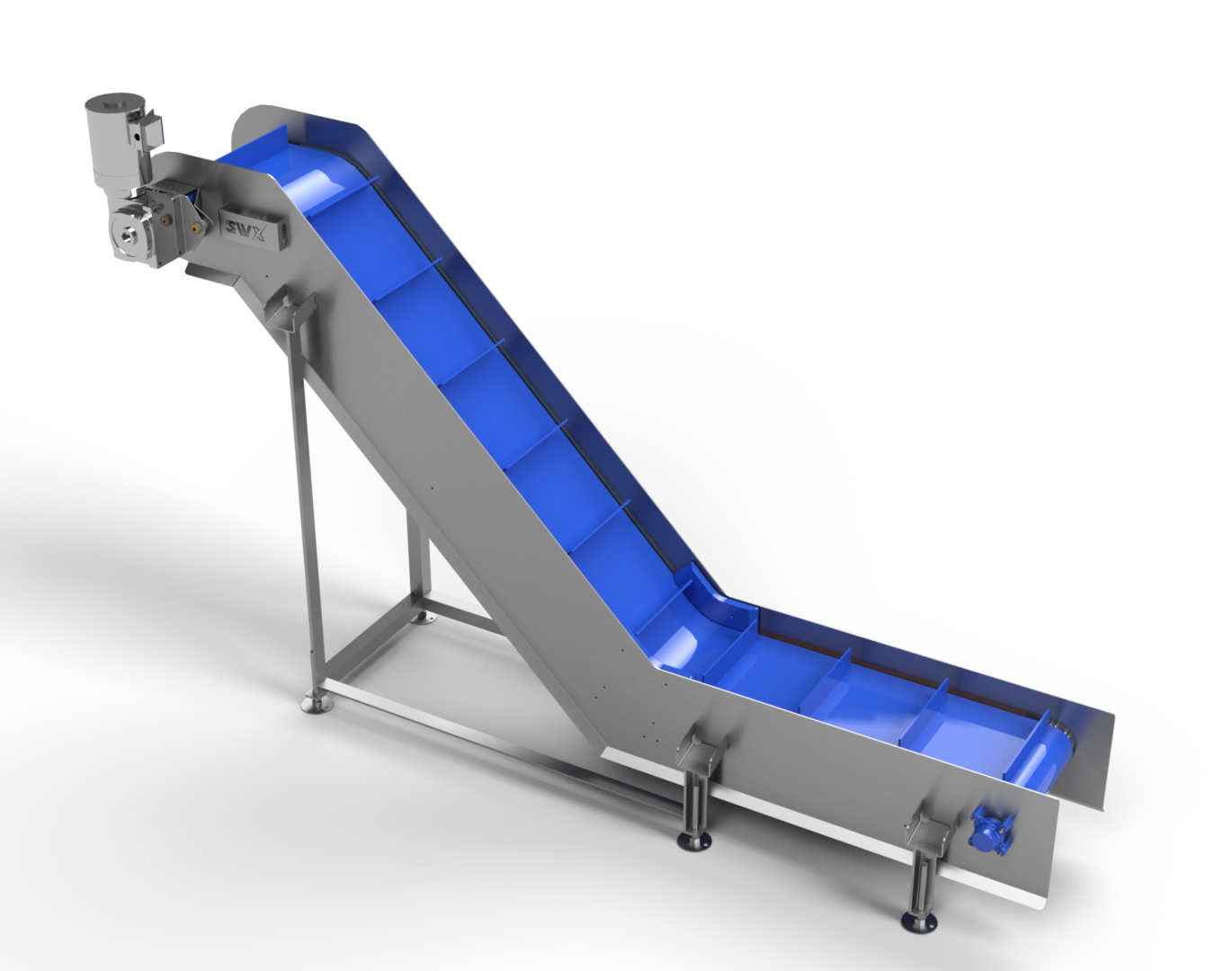

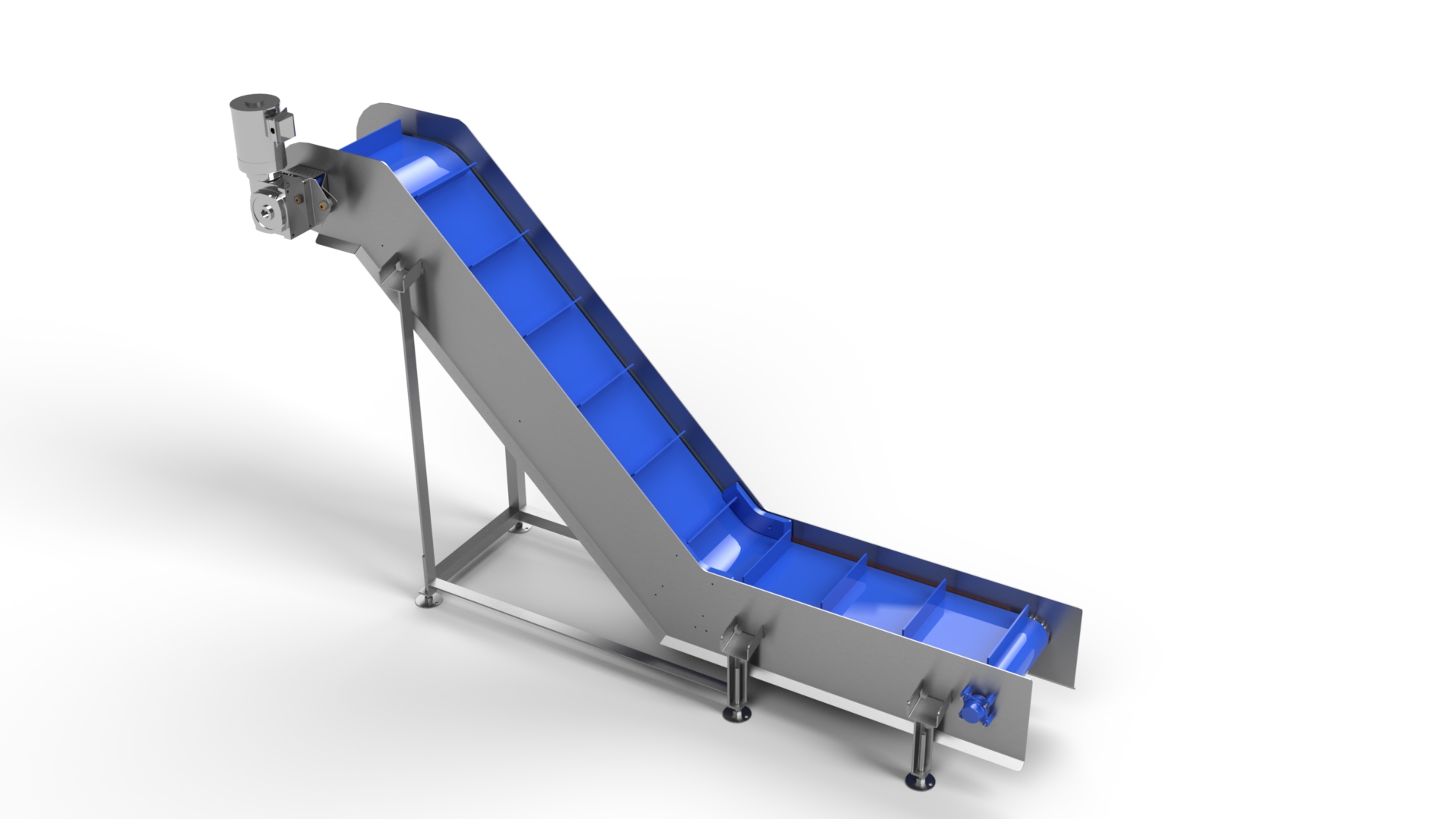

Incline Conveyor

Food Safety & Benefits

•

Versatile Applications: Transports materials vertically between different elevations in production, storage, or distribution.

•

Key Roles: Connects various production stages, facilitates bulk material handling, and feeds products into machinery.

•

Industries Served: Common in agriculture, mining, food processing, logistics, and manufacturing.

•

Efficiency Boost: Speeds up material transport, reduces manual handling, and integrates workflows.

•

Space-Saving Design: Optimizes floor space by utilizing vertical movement.

•

Cost Reduction: Lowers labor costs and minimizes risks associated with manual handling.

•

Safety Enhancement: Reduces workplace accidents by automating material movement.

•

Customizable Features: Tailored with cleats, sidewalls, and belts for specific material needs.

•

Durability: Built to withstand heavy-duty use and harsh environments.

•

Energy Efficiency: Incorporates energy-saving motors and optimized performance designs.

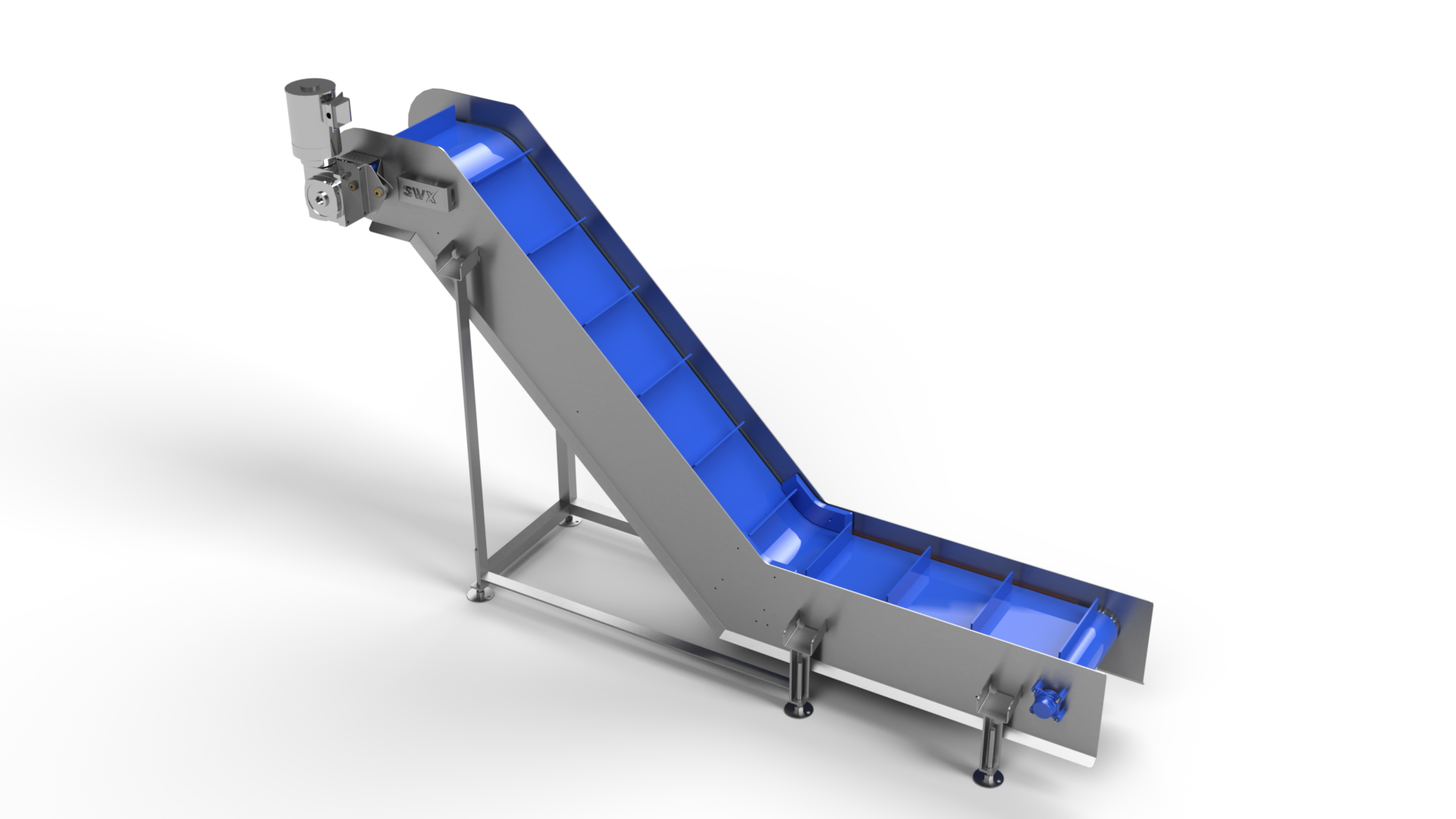

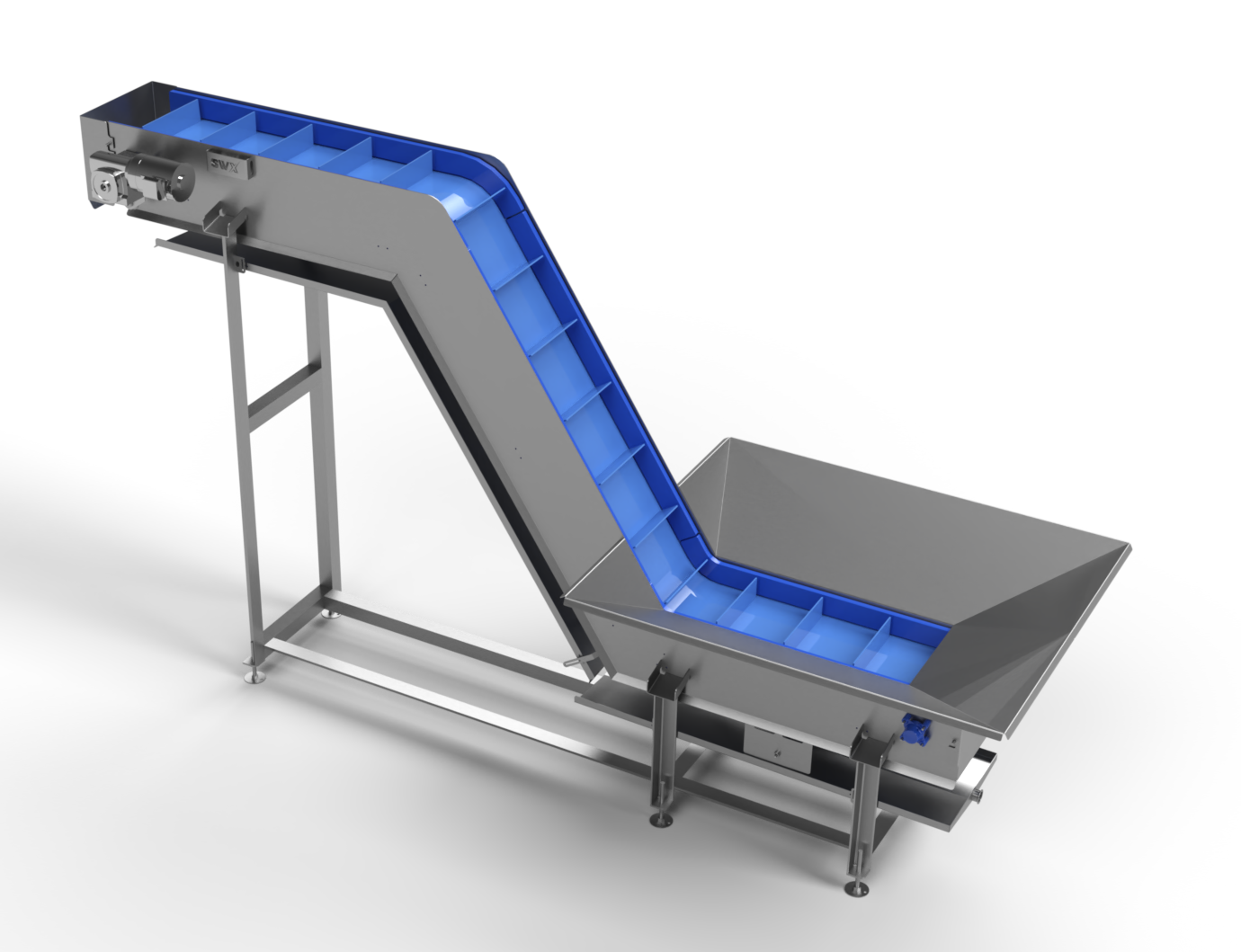

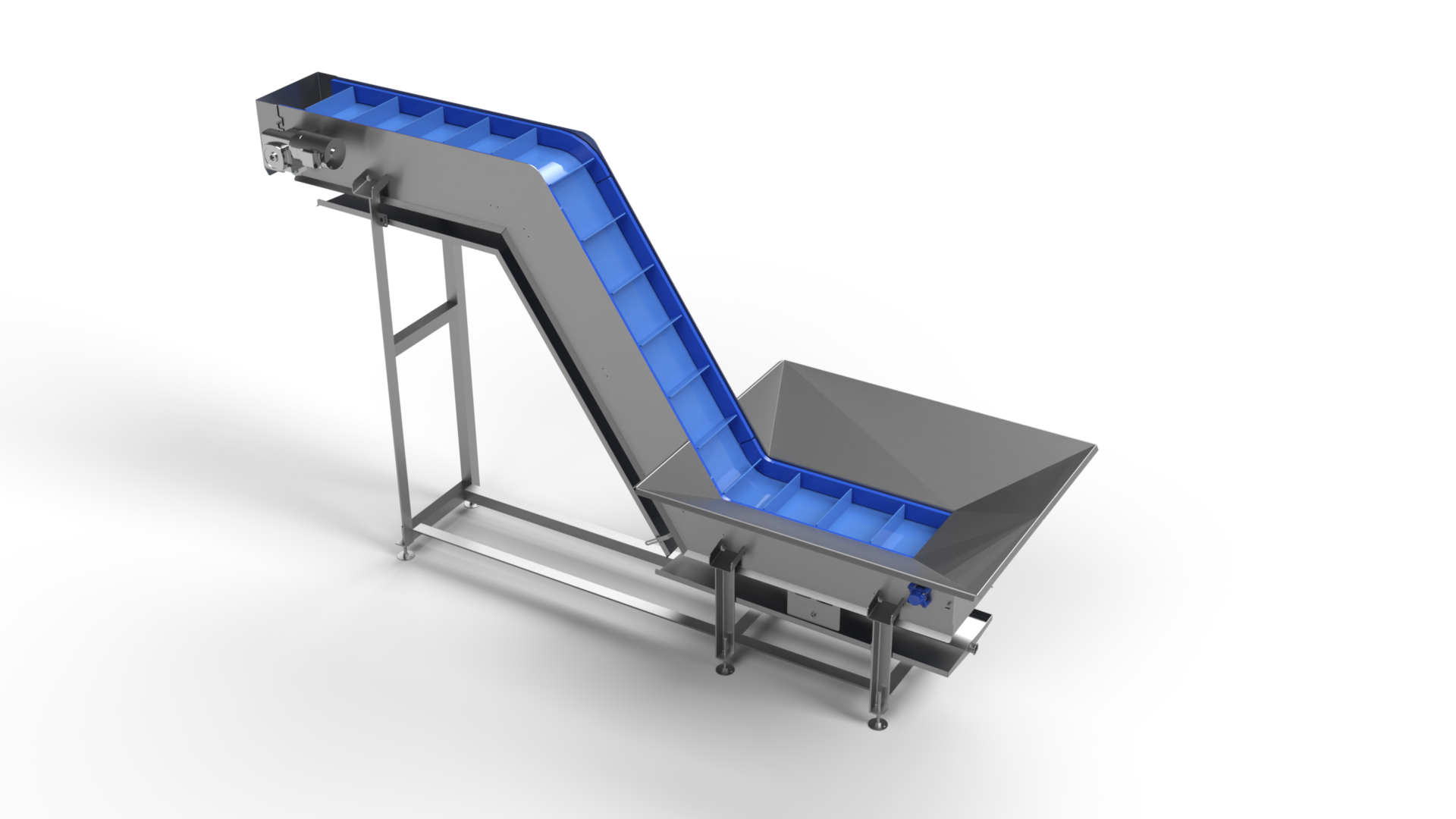

Hopper Incline Conveyor

Food Safety & Benefits

•

Versatile Applications: Combines a hopper and conveyor belt to transport bulk materials like grains, sand, powders, or small parts at an upward angle.

•

Key Roles: Hopper used for dumping large quantities of product, while the conveyor separates and moves materials to different levels in production, packaging, and food processing.

•

Industries Served: Ideal for agriculture, food processing, recycling, waste management, and automated packaging systems.

•

Efficient Material Transport: Minimizes spillage, especially at steep angles, while the hopper ensures bulk materials are handled smoothly.

•

Space-Saving Design: The inclined hopper-conveyor setup optimizes floor space by transporting materials vertically or at an angle.

•

Customizable Features: Adjustable hopper size, conveyor angle, and belt types tailored to suit specific materials and capacities.

•

Durability & Reliability: Built with robust materials to handle heavy-duty applications, requiring low maintenance due to its simple construction.

•

Enhanced Productivity: The hopper feeds large quantities into the conveyor, speeding up material handling and improving workflow efficiency.

•

Safety: Reduces workplace injuries by automating material handling and minimizing manual lifting.

•

Cost-Effective: Lowers labor costs by automating the material transfer process and offers energy-efficient options for reduced operational expenses.

•

Versatility: Capable of handling a wide range of materials from powders to bulkier items, ideal for industries like agriculture, food, pharmaceuticals, and construction.

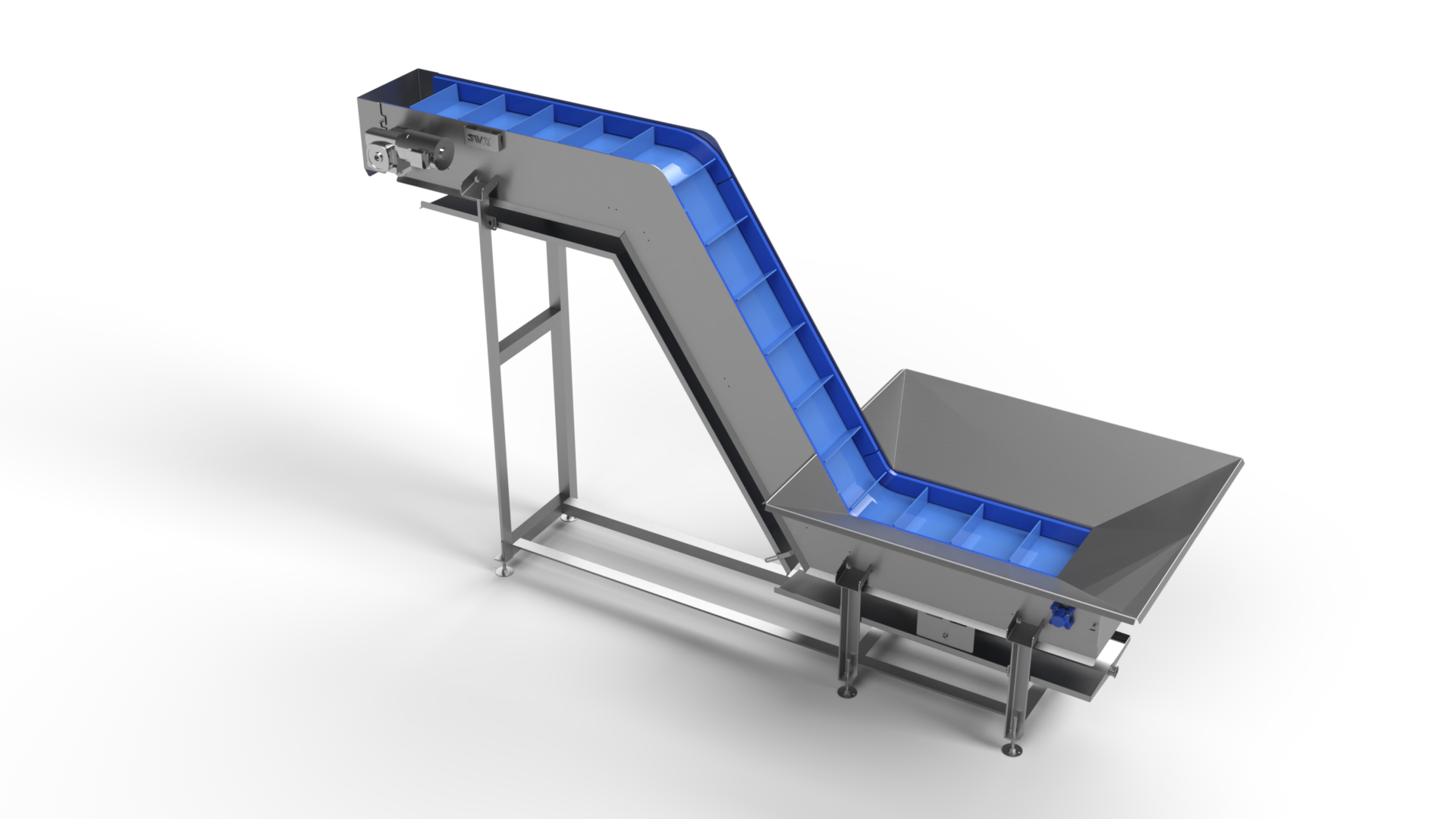

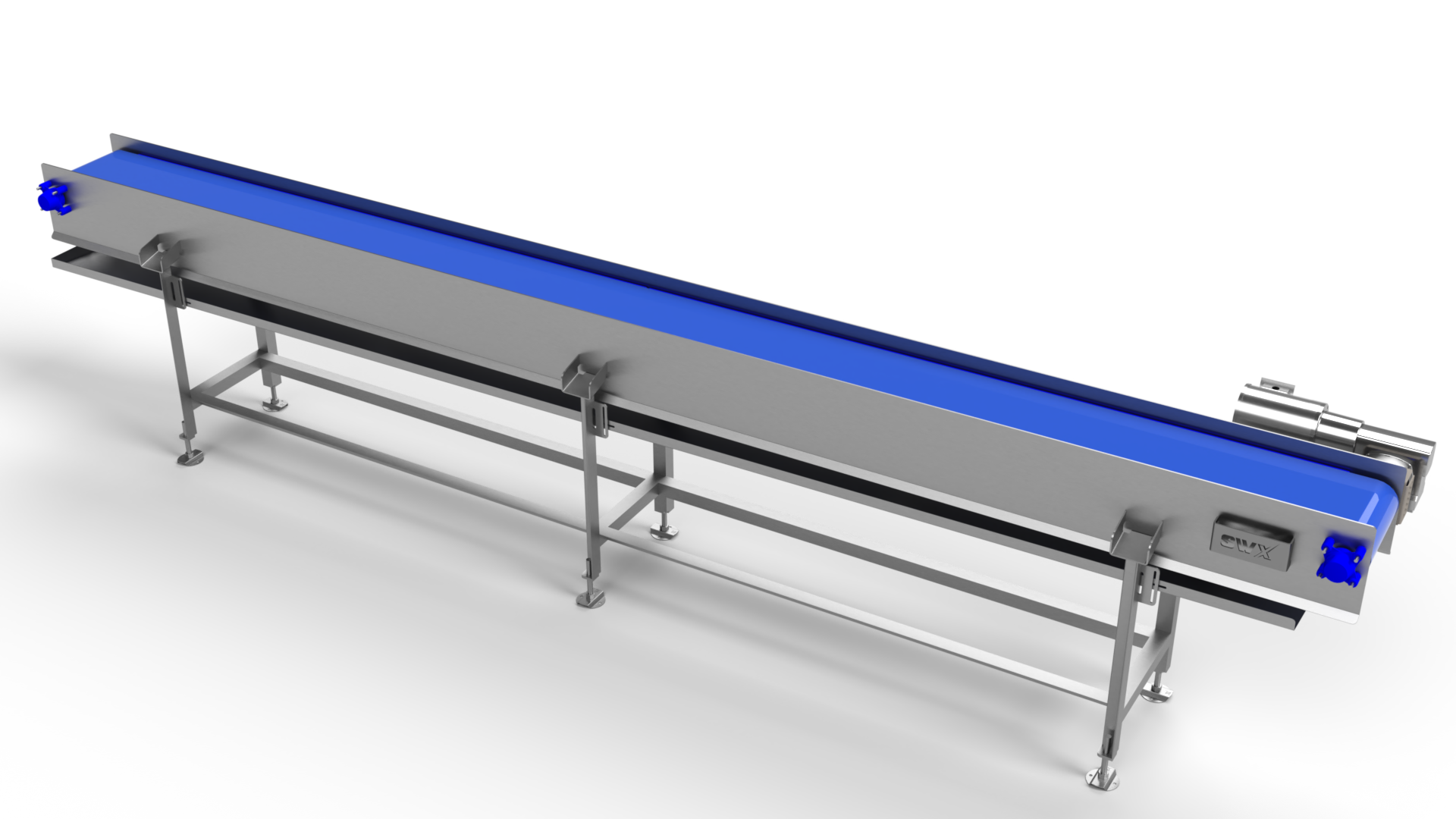

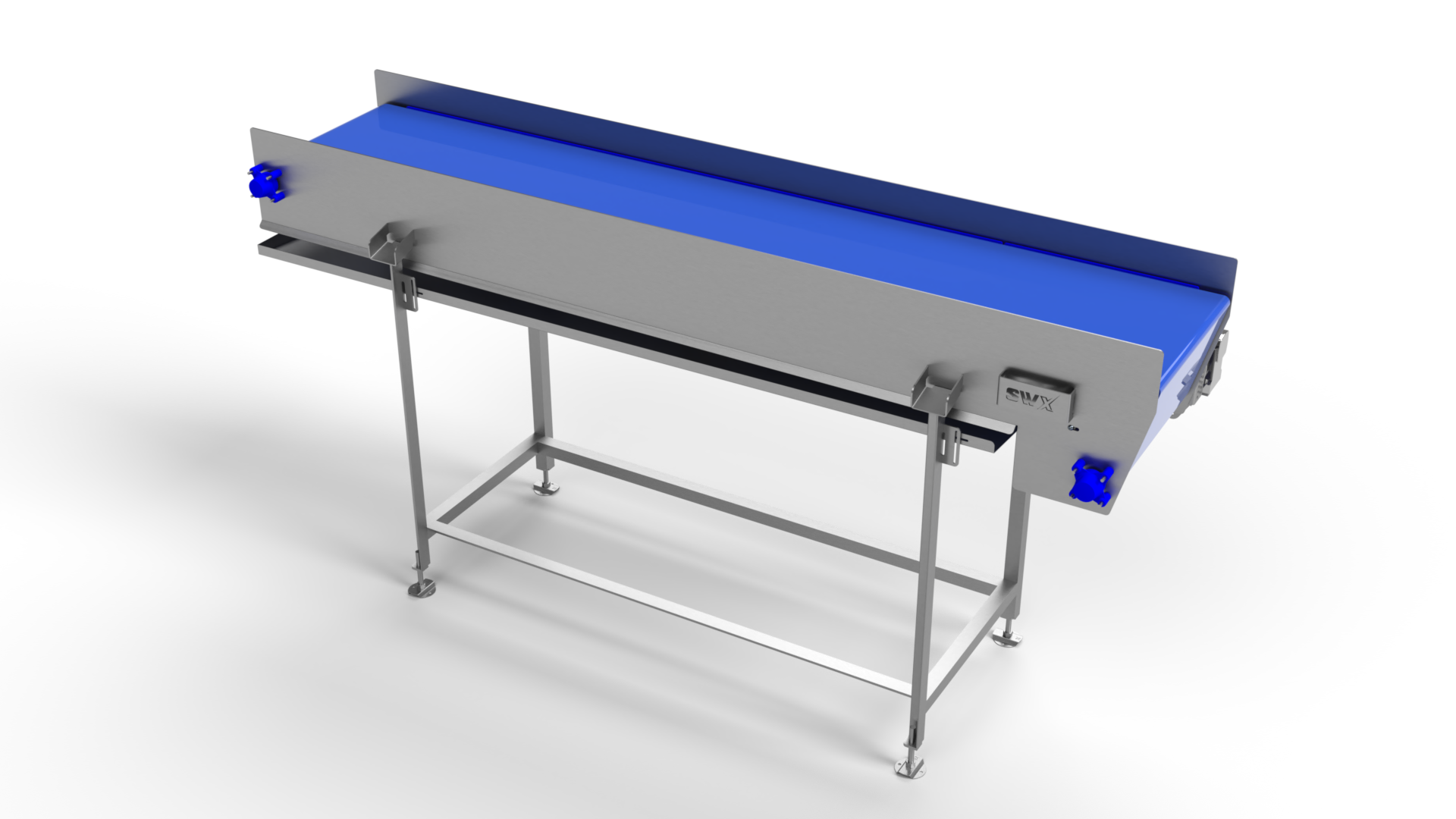

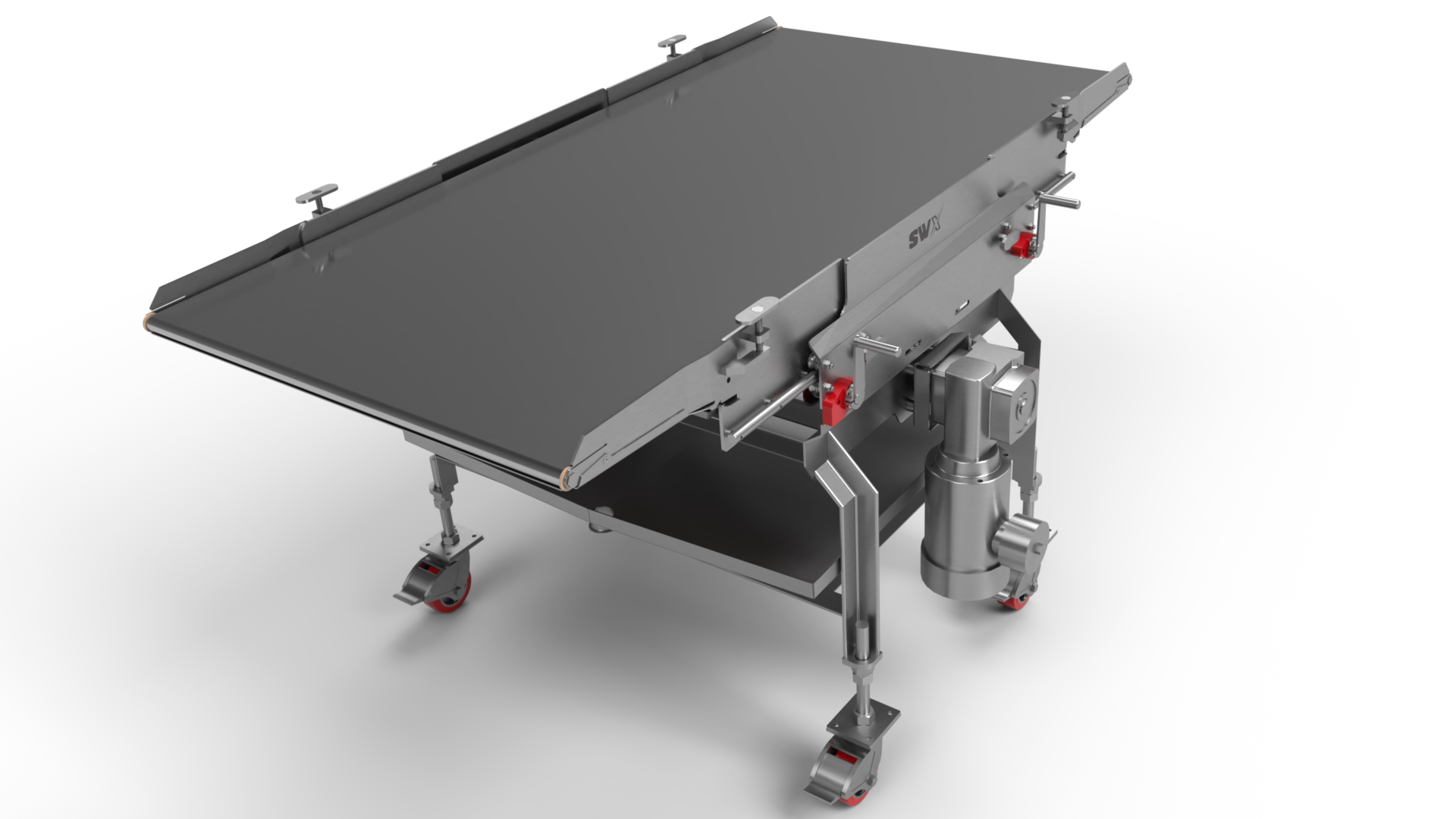

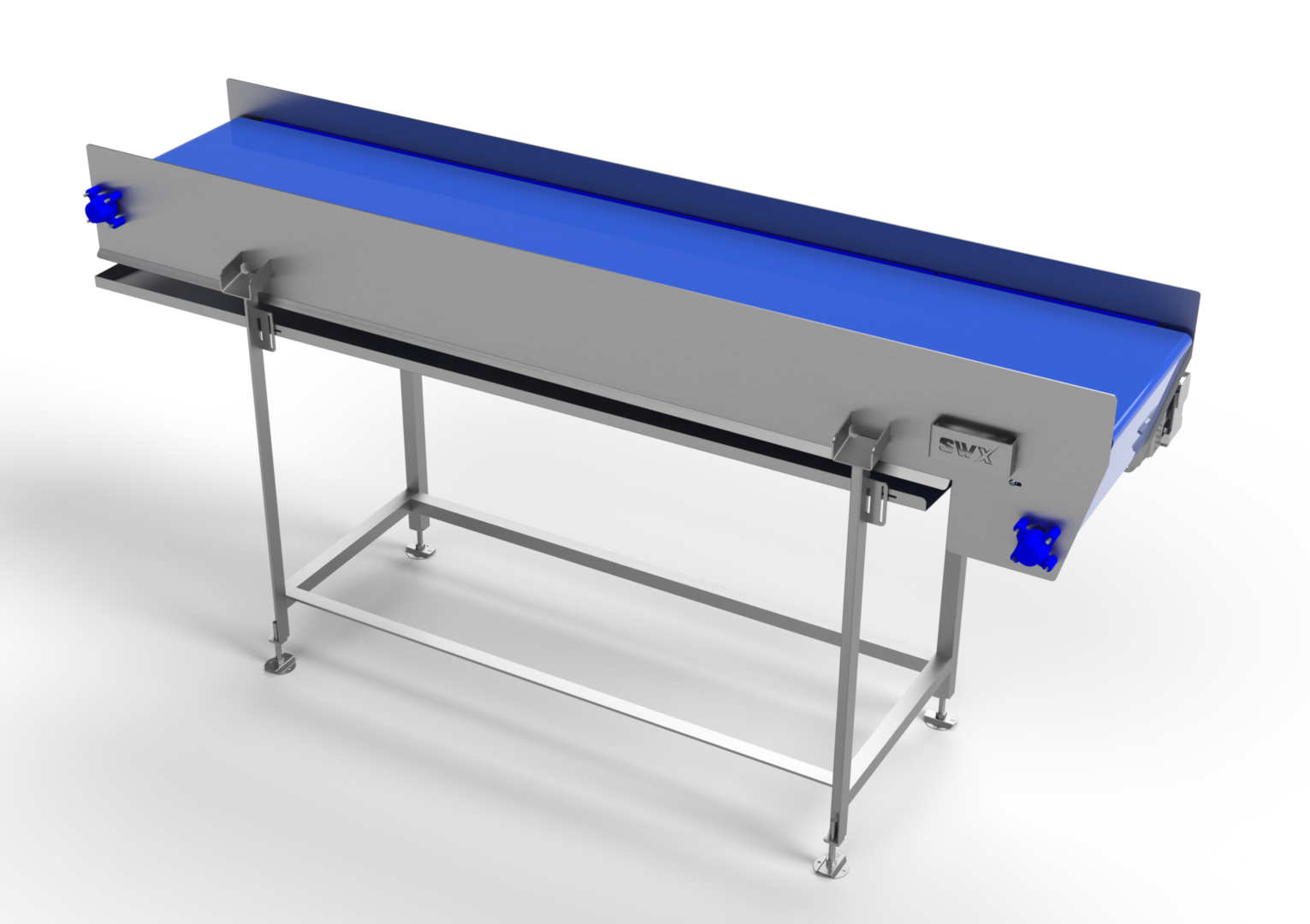

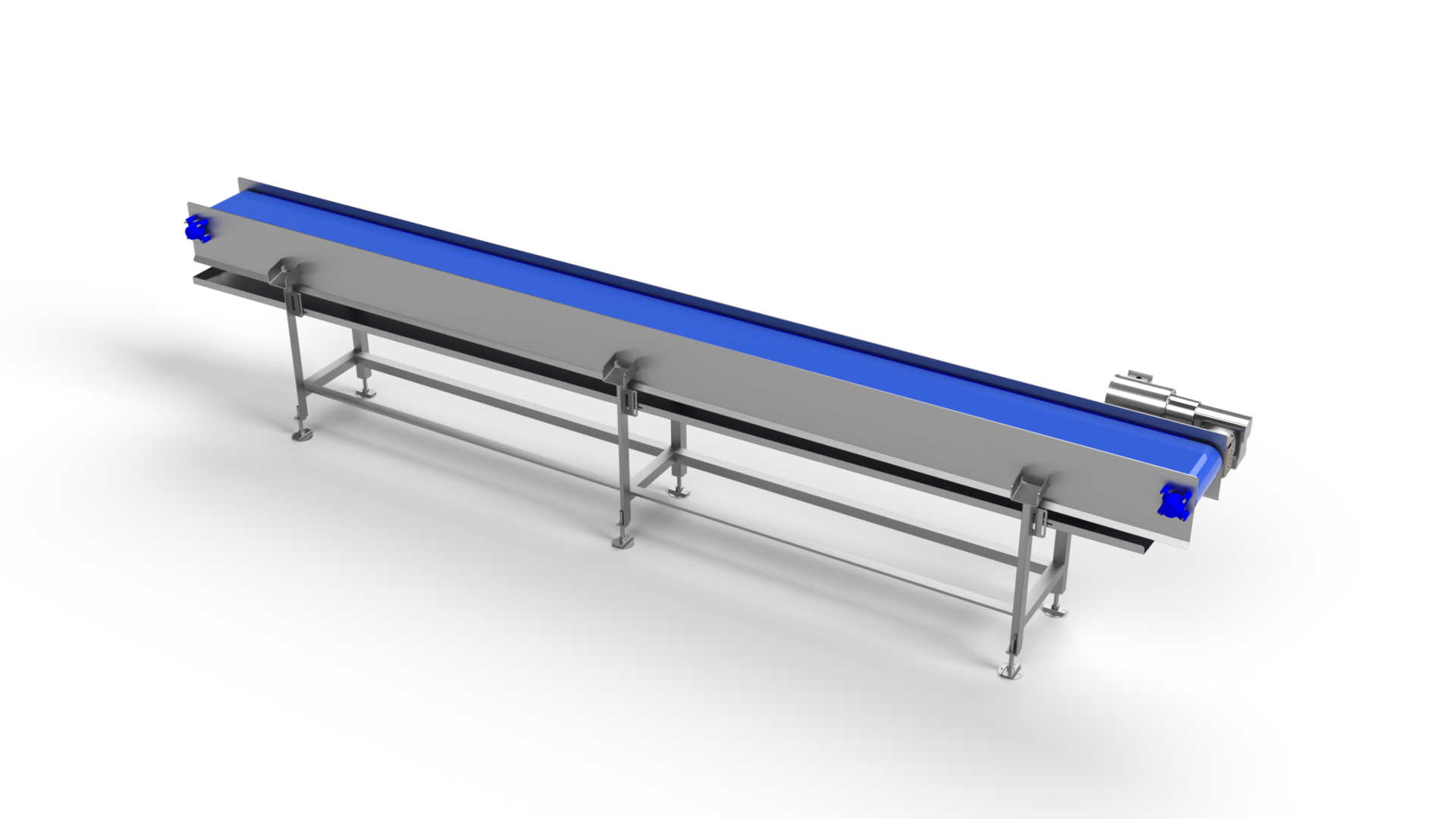

Straight CNV Master

Food Safety & Benefits

•

Versatile Applications: Transports materials over a linear distance in manufacturing, packaging, and distribution.

•

Key Roles: Integrates into assembly lines, supports sorting, and facilitates loading/unloading in warehouses.

•

Industries Served: Common in manufacturing, food processing, pharmaceuticals, and logistics.

•

Efficiency Boost: Speeds up material transport, reduces manual handling, and integrates workflows.

•

Space-Saving Design: Optimizes floor space by efficiently moving materials along a linear path.

•

Cost Reduction: Lowers labor costs and minimizes wear on materials.

•

Safety Enhancement: Reduces workplace injuries by automating material handling.

•

Customizable Features: Can be tailored with various conveyor belts (rubber, steel, modular) for different needs.

•

Durability: Built to withstand heavy loads with low maintenance requirements.

•

Scalability: Easily extendable and adaptable to growing operational needs.

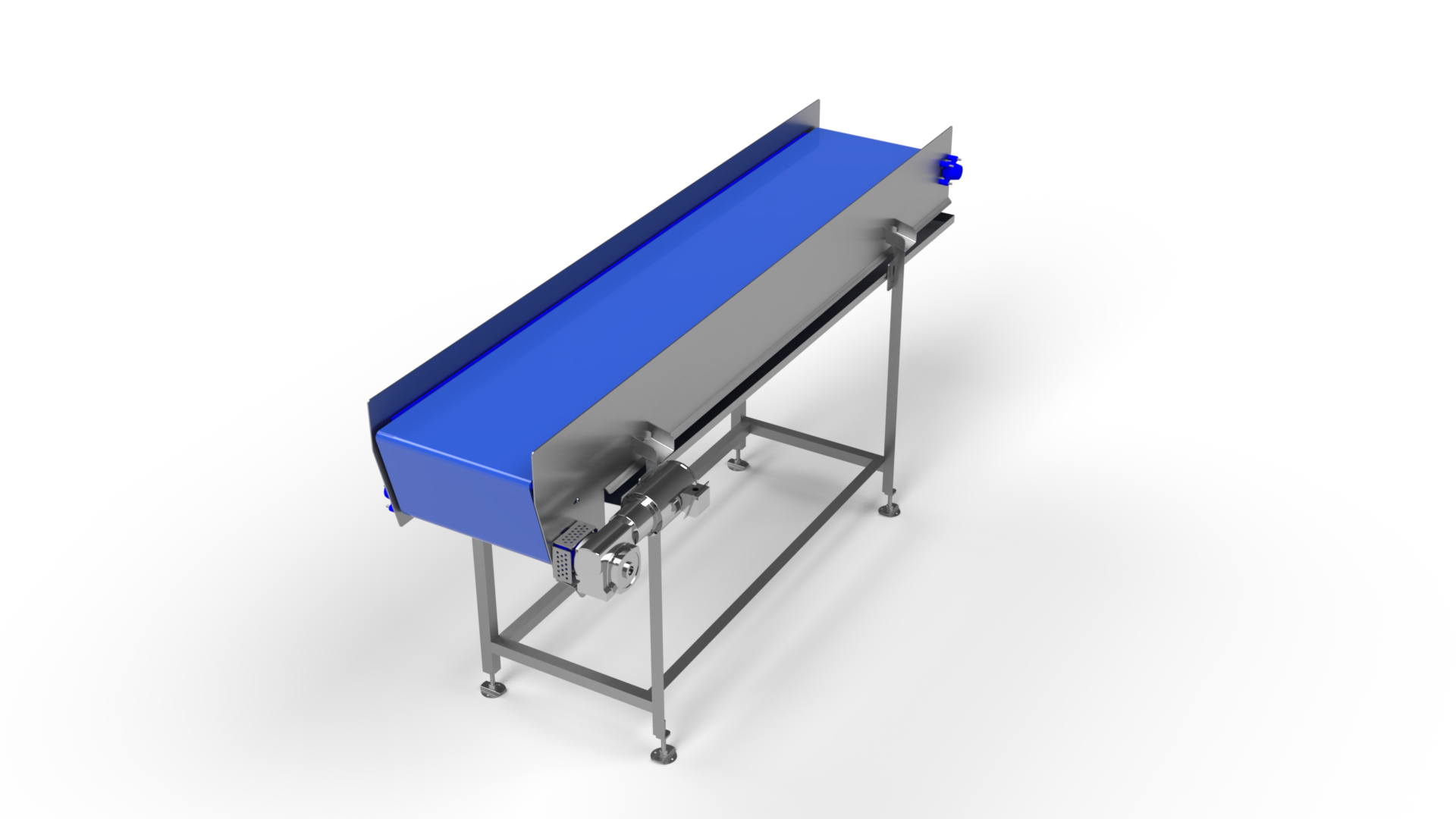

Tight Transfer Conveyor

Food Safety & Benefits

· Versatile Applications: Tight transfer conveyors are used for transferring small, delicate, or high-value products seamlessly between conveyor systems or machinery, ensuring precise positioning during transitions.

· Key Roles: Ensure smooth product movement, minimize damage or misalignment, maintain product orientation, and support precision in inspection, sorting, and quality control tasks.

· Industries Served: Widely utilized in food and beverage production, pharmaceutical manufacturing, electronics assembly, packaging operations, and other precision-driven industries.

· Efficiency Boost: Streamlines production lines by reducing product loss, minimizing downtime, and optimizing operational performance.

· Hygiene and Compliance: Designed to meet stringent standards such as FDA and HACCP, ensuring cleanliness and minimizing contamination risks in food and pharmaceutical environments.

· Durability: Constructed with robust materials to handle continuous use and high-speed operations, ensuring long-term reliability in demanding conditions.

· Safety Features: Prevent product jamming or dropping, reduce risks to operators, and maintain consistent line performance.

· Customizable Designs: Adaptable to specific product dimensions, weights, and conveyor layouts, with options like variable speeds, integrated sensors, and tailored configurations.

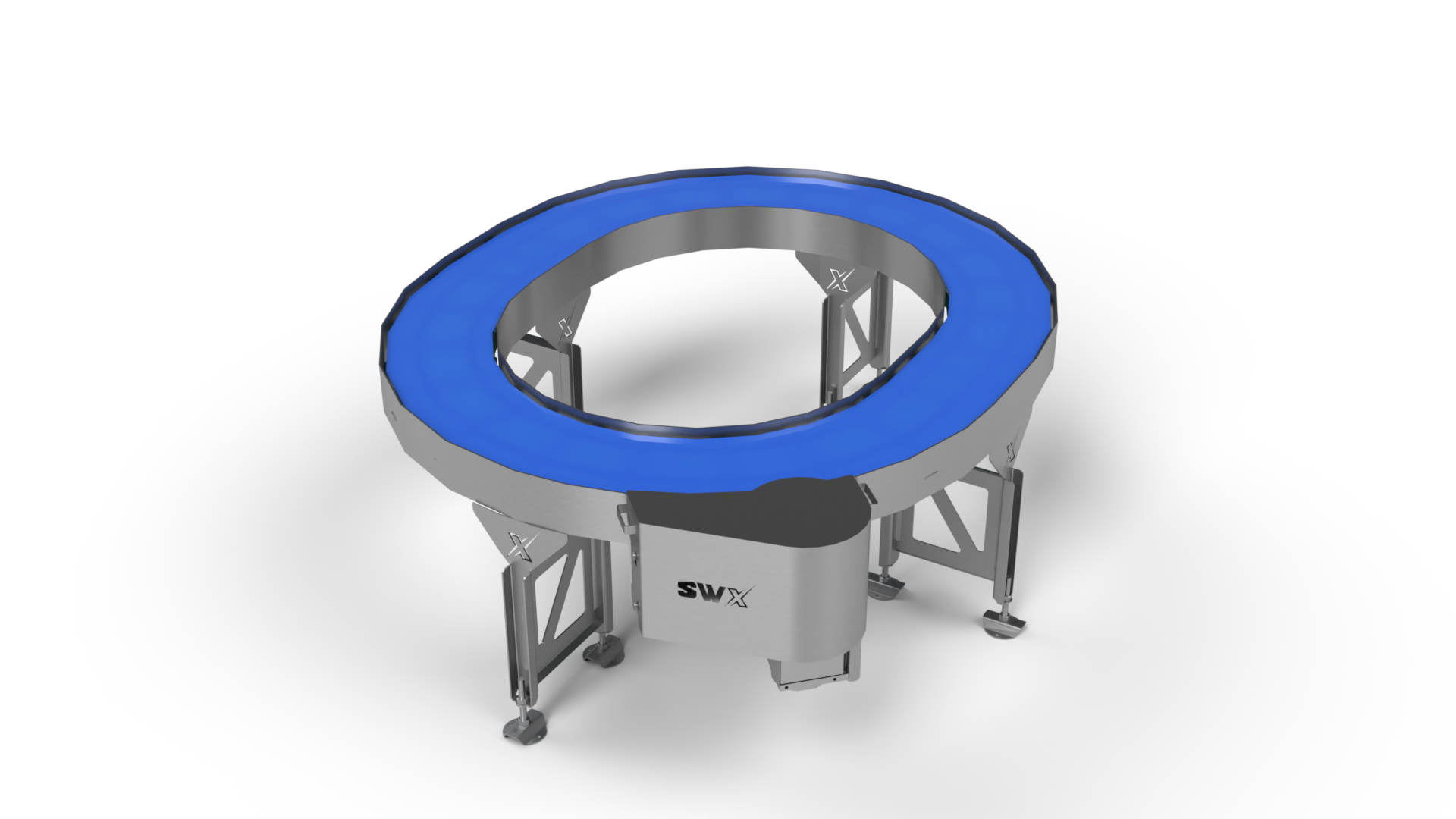

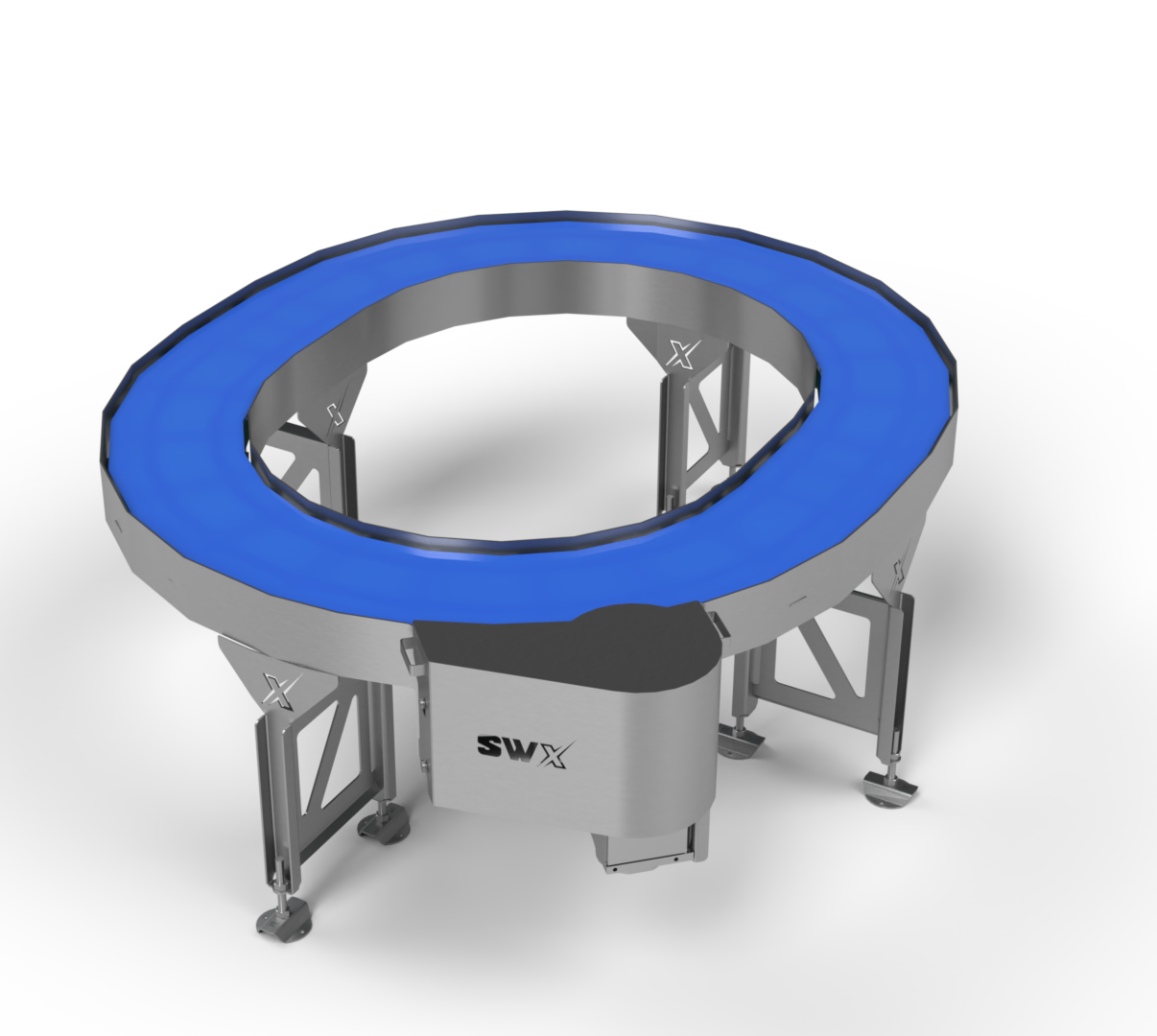

Racetrack Conveyor

Food Safety & Benefits

•

Versatile Applications: Oval conveyors are used for transporting products through packaging, assembly, inspection, sorting, and storage processes.

•

Key Roles: Enhance workflow by maintaining continuous product flow, balancing supply and demand, and supporting efficient production and packaging operations.

•

Industries Served: Common in food and beverage, pharmaceutical, manufacturing, and consumer goods industries.

•

Efficiency Boost: Automates material handling, reducing manual labor, minimizing errors, and increasing overall productivity.

•

Space Optimization: The oval design maximizes floor space utilization, ideal for facilities with limited room for linear conveyor systems.

•

Durability: Built with robust materials, such as stainless steel, for long-term reliability and use in demanding industrial environments.

•

Hygiene and Compliance: Meets regulatory standards for cleanliness and sanitation in industries like food and pharmaceuticals.

•

Safety Features: Reduces workplace injuries by automating repetitive tasks and providing secure, stable operation.

•

Customizable Designs: Offers tailored configurations to fit specific needs, including size, speed, load capacity, and integration with other equipment.

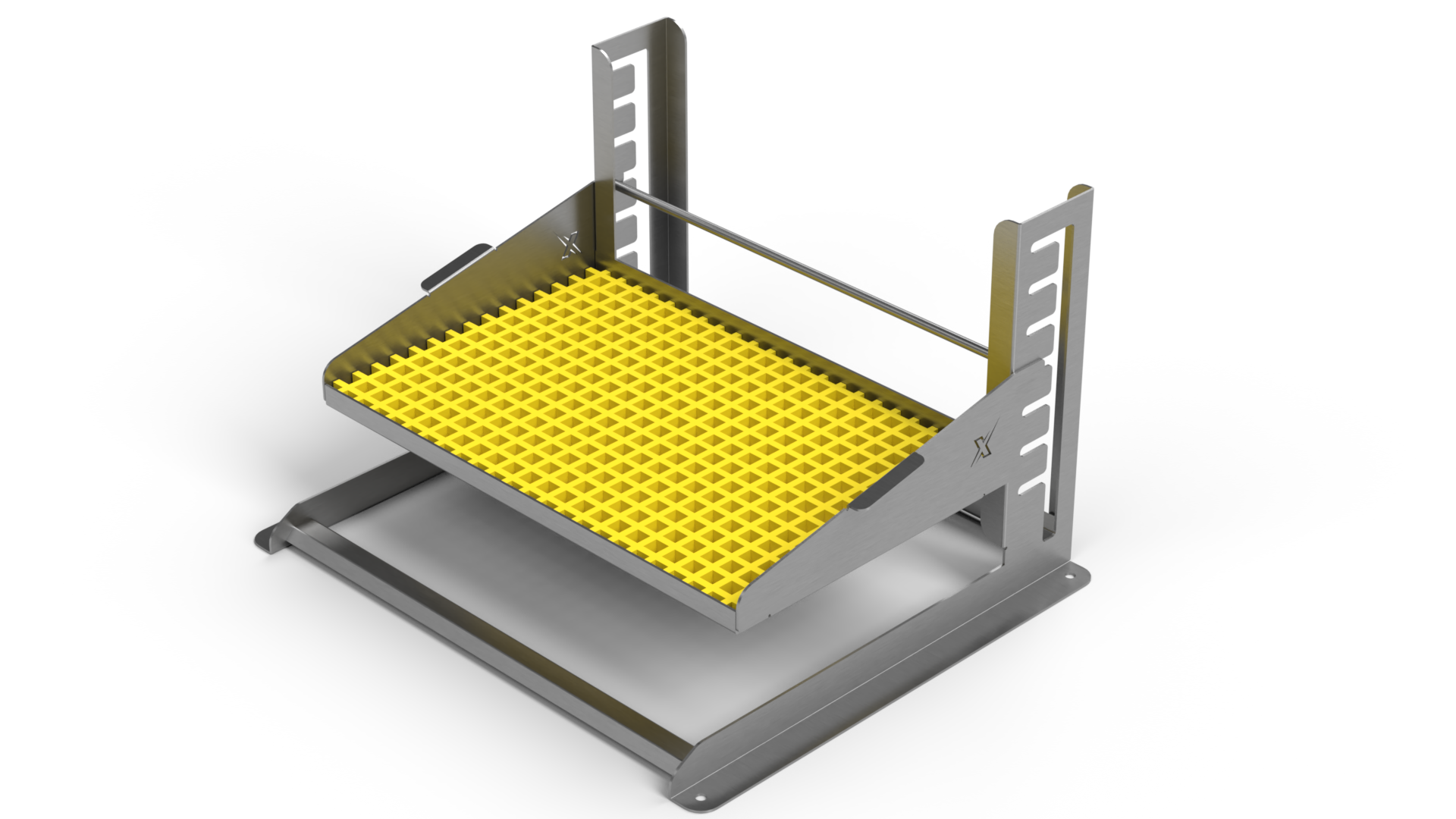

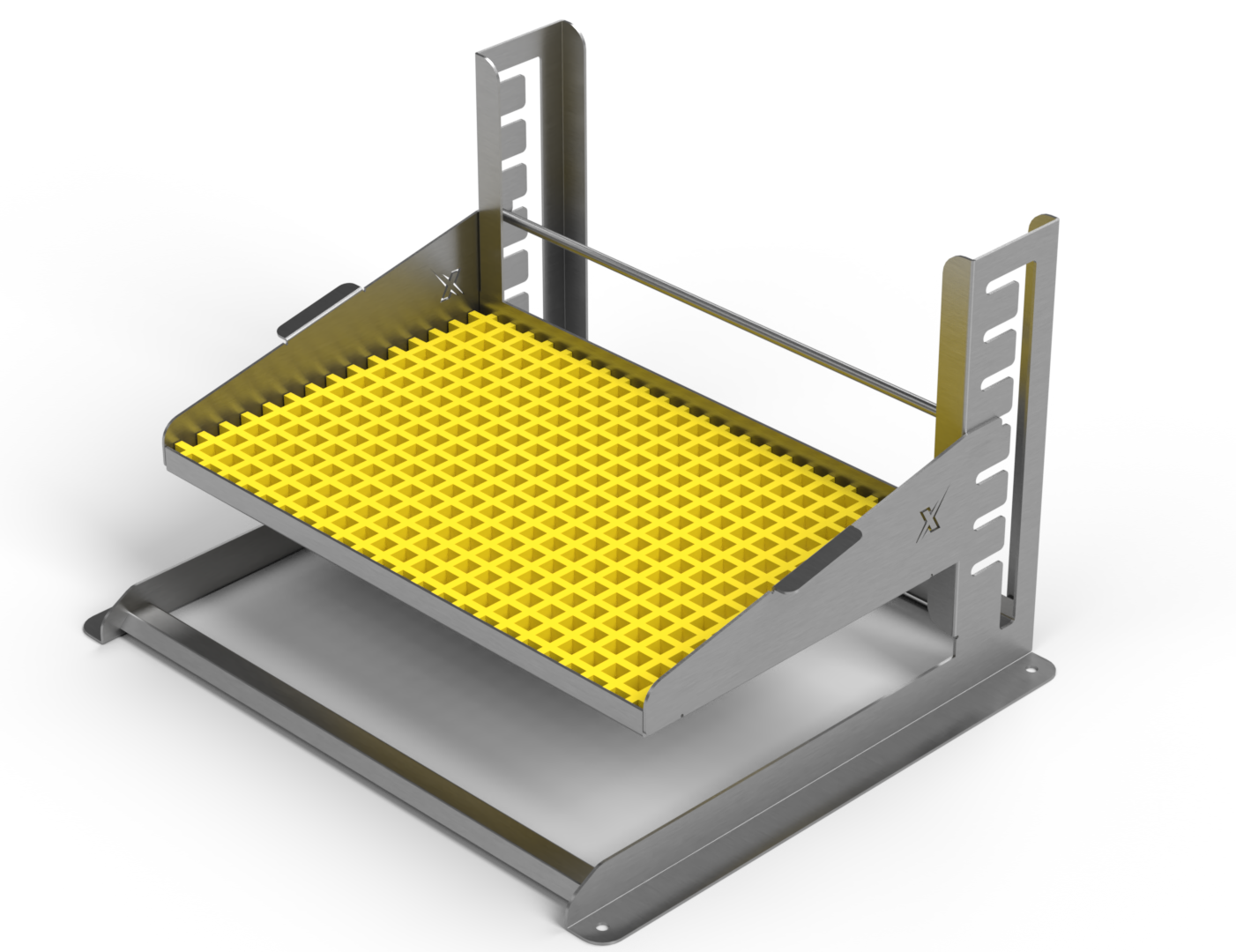

Adjustable Ergo Stand - Floor Mount

Food Safety & Benefits

•

Versatile Applications: Adjustable steps in manufacturing accommodate different product specifications, materials, and operational needs.

•

Key Roles: Enables quick changeovers, tailored production, and prototyping/testing without permanent equipment changes.

•

Customization: Allows production to be tailored to meet specific customer requirements without new setups.

•

Process Optimization: Facilitates fine-tuning for maximum efficiency and quality during production.

•

Ergonomics & Worker Safety: Adjustable physical steps improve worker comfort and safety by reducing strain.

•

Adaptation to Material Variability: Ensures consistent output despite variations in raw materials.

•Cost Savings: Reduces the need for additional machinery and tools, lowering capital expenditures.

•

Increased Efficiency: Minimizes waste by enabling precise control and adjustments.

•

Improved Product Quality: Fine-tuning ensures consistent adherence to quality standards.

•

Reduced Inventory Needs: Eliminates the need for dedicated equipment for each product variation, saving space.

•

Sustainability: Reduces waste and energy consumption by optimizing processes for efficiency.

Single Station Hand Wash

Food Safety & Benefits

•

Versatile Applications: Industrial stainless-steel sinks are used in food processing, healthcare, industrial settings, educational labs, and public facilities.

•

Key Roles: Essential for cleaning, sanitizing, and washing tools, machinery, and equipment in various industries.

•

Industries Served: Common in food processing, healthcare, manufacturing, research labs, and public spaces.

•

Durability: Resistant to corrosion, rust, and wear, ideal for environments with heavy use and exposure to chemicals.

•

Hygiene: Non-porous surface prevents bacterial buildup, easy to clean and sterilize to meet sanitary standards.

•

Aesthetic Appeal: Sleek, modern design that fits industrial and commercial spaces.

•

Versatility: Available in various sizes and configurations, customizable with features like drainboards and integrated faucets.

•

Heat & Chemical Resistance: Withstands high temperatures and strong cleaning agents without degrading.

•

Cost-Effective: Low maintenance and long-lasting, reducing the need for frequent replacements.

•

Safety Enhancement: Reduces contamination risks in food and healthcare industries due to hygienic design.

•

Space Optimization: Can be customized to fit specific operational needs and save space in busy environments.

Work Table

Food Safety & Benefits

•

Versatile Applications: Stainless steel tables are used in food preparation, manufacturing workstations, storage, and cleaning stations.

•

Key Roles: Serve as surfaces for assembling products, preparing ingredients, storing materials, and cleaning tools in various industries.

•

Industries Served:

Common in food processing, restaurants, manufacturing, and pharmaceutical industries.

•

Durability: Resistant to rust, corrosion, and staining, ideal for demanding environments with exposure to moisture, heat, or chemicals.

•

Hygiene: Non-porous, easy-to-clean surface reduces bacterial contamination, critical for food safety.

•

Strength & Stability:

Can support heavy loads, suitable for both manufacturing tasks and food prep.

•

Resistance to High Temperatures: Withstands high heat, perfect for cooking or manufacturing areas with temperature exposure.

•

Aesthetic & Professional Appearance:

Sleek, modern look associated with cleanliness and professionalism.

•

Chemical Resistance: Resists a wide range of chemicals, ideal for environments using cleaning agents or other substances.

•

Low Maintenance: Requires minimal upkeep, making it cost-effective and long-lasting.

Table Single & Double Swivel Totes

Food Safety & Benefits

· Versatile Applications: Ideal for transporting tools, office supplies, groceries, laundry, and event materials.

· Key Roles: Organizes and moves items efficiently, reducing the effort and time spent carrying heavy or bulky objects.

· Industries Served: Common in-home use, remote work, retail, events, trade shows, and food plants.

· Efficiency Boost: Enhances mobility and quick access to items, increasing productivity and reducing downtime.

· Space-Saving Design: Dual compartments help organize and separate items, keeping everything accessible and tidy.

· Durability: Built with strong materials and wheels that handle heavy loads and rough usage.

· Enhanced Mobility: Wheels provide easy transportation across various surfaces, making it ideal for people on the move.

· Customizable Features: Options for multiple compartments, dividers, or pockets for specific organization needs.

· Timesaving: Reduces the need for multiple trips by combining storage and transport in one unit.

· Convenience:

Offers a compact, collapsible design that can be stored away when not in use, saving space in smaller area.

Lung Cyclone

Food Safety & Benefits

•

Versatile Applications: Cyclones are used for drying, cooling, boiling, reacting, pneumatic conveying, combustion, and processing a wide range of materials, from food ingredients and plastic pellets to corrosive and high-temperature substances in petrochemicals.

•

Key Roles: Enhance process efficiency by effectively separating materials, improving safety, and supporting critical industrial operations.

•

Industries Served: Commonly used in manufacturing, food processing, petrochemical production, and material handling operations.

•

Efficiency Boost: Optimize processes by improving material flow, reducing energy consumption, and minimizing downtime.

•

Material Handling: Handle thousands of materials, including abrasive, toxic, and heat-sensitive substances, while maintaining system integrity.

•

Durability: Engineered with robust materials to withstand high temperatures, corrosive environments, and demanding industrial conditions.

•

Hygiene and Compliance: In food and pharmaceutical applications, cyclones meet strict regulatory standards for cleanliness, safety, and material purity.

•

Safety Features: Designed to manage hazardous materials and high-pressure environments safely, minimizing risks during operation.

•

Customizable Designs: Offer tailored solutions, including configurations for specific materials, process requirements, and industry standards.

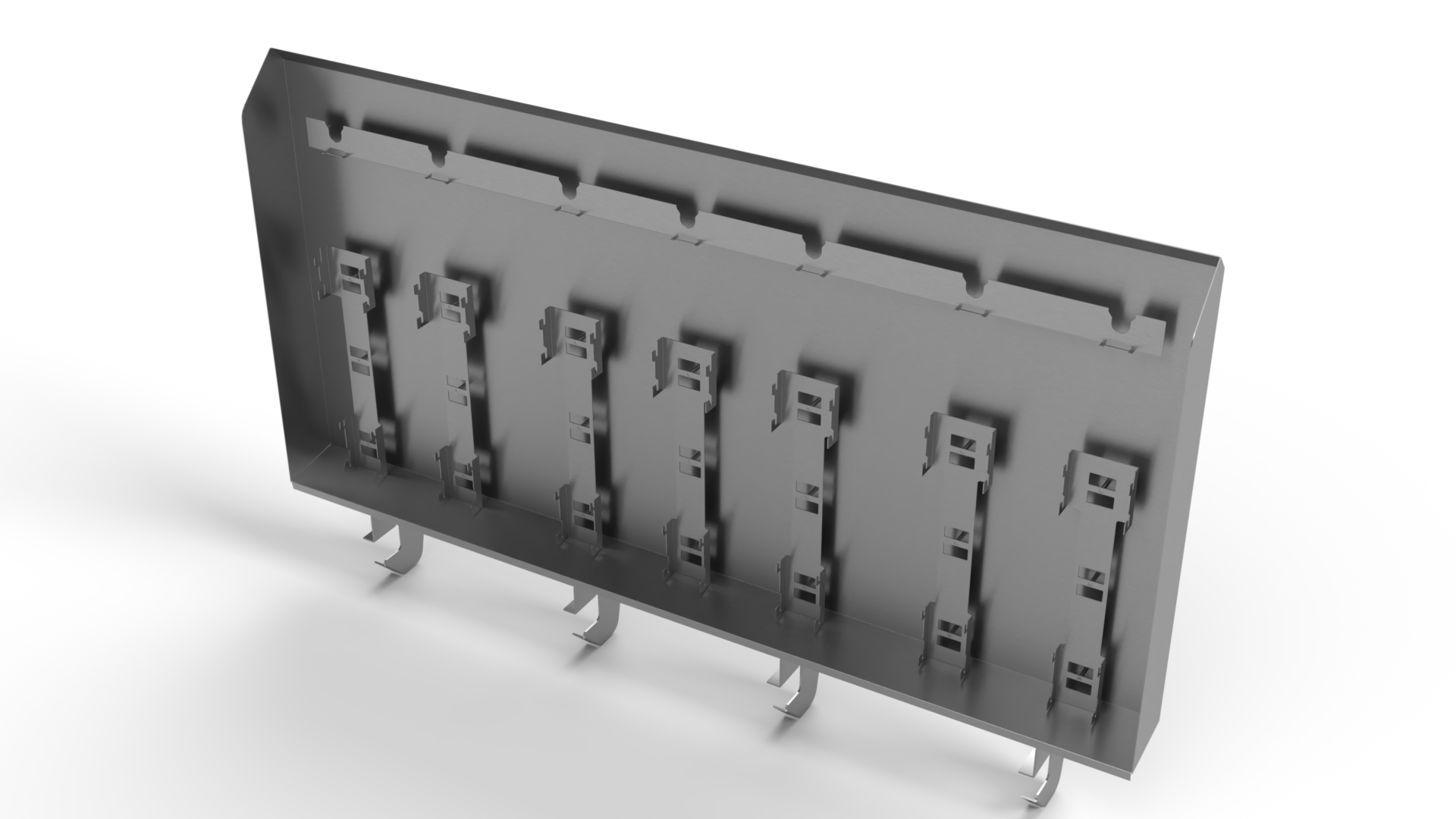

Screen Table

Food Safety & Benefits

- Versatile Applications: Screen tables are used for sorting, grading, separating, debris removal, sieving, filtering, and assisting with drying or cooling during food and manufacturing processes.

- Key Roles: Ensure product quality, improve efficiency, reduce waste, and protect downstream equipment by eliminating contaminants and irregular items.

- Industries Served: Widely utilized in food processing, manufacturing, pharmaceuticals, and industrial operations.

- Efficiency Boost: Streamlines operations by automating separation tasks, reducing manual labor, and increasing throughput.

- Hygiene and Compliance: Designed to meet stringent safety and sanitation standards in food-grade environments.

- Durability: Built with robust, corrosion-resistant materials like stainless steel for long-term performance and easy maintenance.

- Safety Features: Prevent contamination, improve product quality, and ensure the safety of workers and equipment.

- Customizable Designs: Adaptable to specific materials and processes with adjustable screen sizes, multiple screening layers, and tailored configurations.

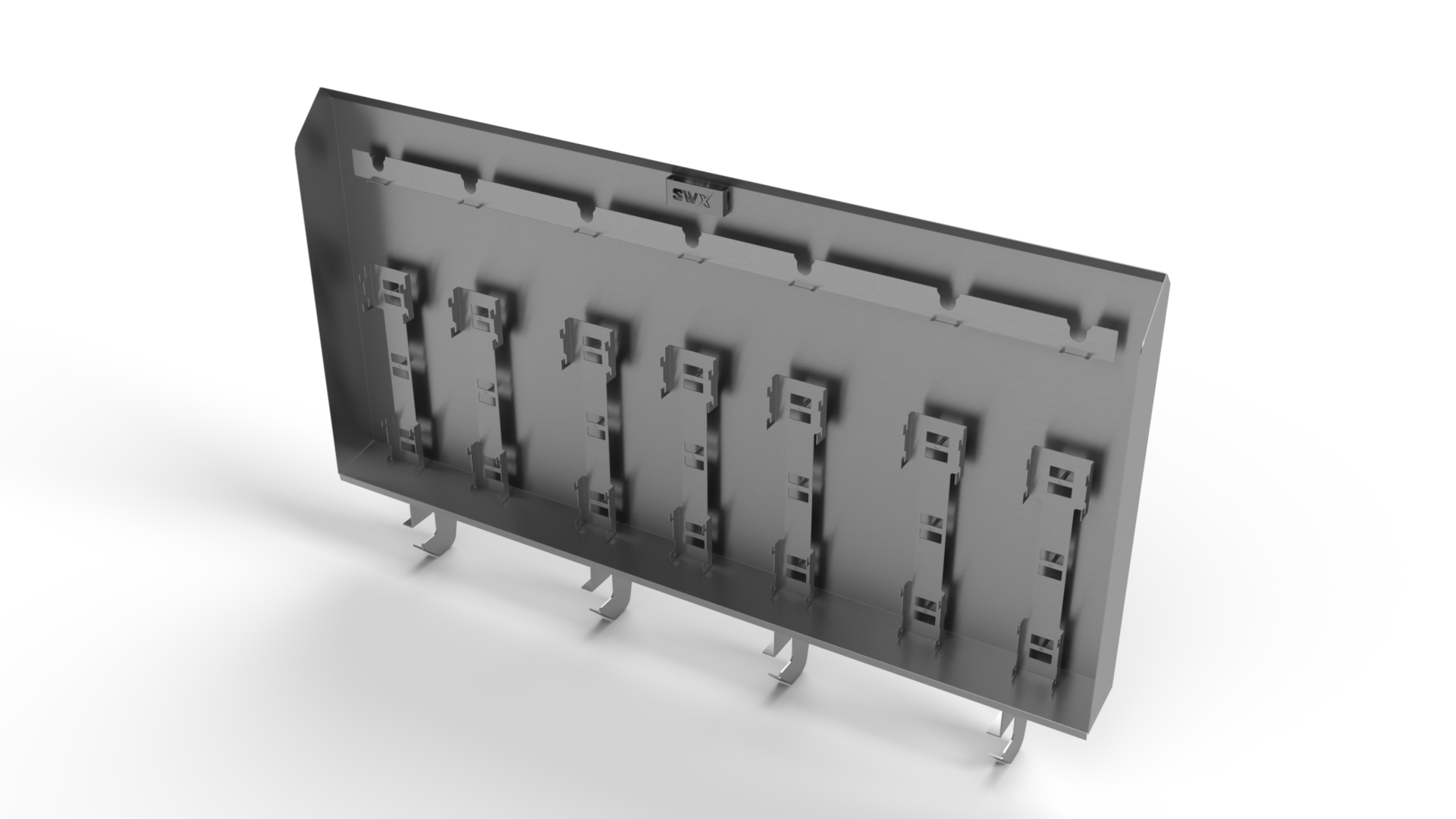

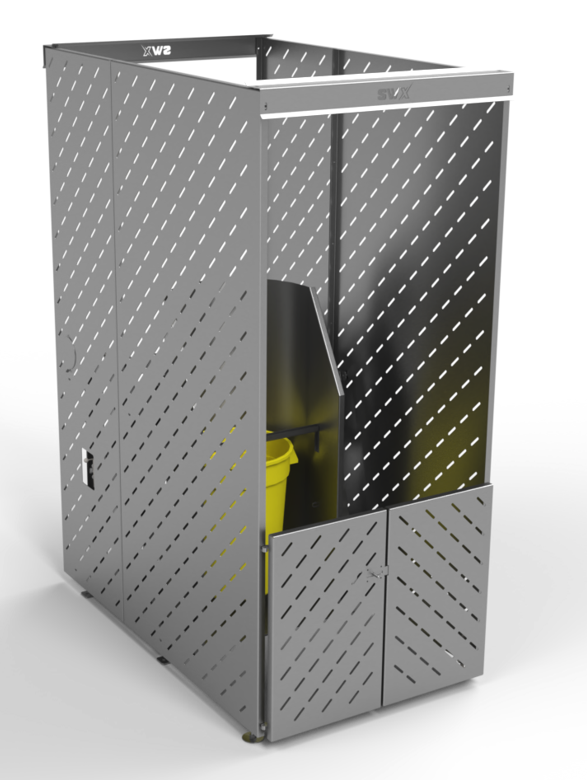

Bucket Wash - Process Platform

Food Safety & Benefits

• Versatile Applications: Bucket washing racks are suitable for cleaning, sanitizing, and drying various containers, including buckets, pails, pans, and lids, making them adaptable to different industry needs.

•

Key Roles: Enhance workflow by ensuring thorough cleaning and sanitization, reducing cross-contamination risks, improving worker safety, and complying with food safety regulations.

•

Industries Served: Widely used in bakeries, dairies, food processing plants, beverage production facilities, and other high-volume operations.

•

Efficiency Boost: Speeds up the cleaning process by accommodating multiple containers simultaneously, reducing manual labor, and lowering operational costs.

•

Space Optimization: Keeps cleaning areas organized by holding containers securely, maximizing floor space and improving workflow efficiency.

•

Durability: Constructed with robust, often food-grade materials to protect containers from wear and tear during cleaning, ensuring long-term reliability.

•

Hygiene and Compliance: Meets stringent regulatory standards such as FDA and HACCP, ensuring cleanliness and safety in food-related environments.

•

Safety Features: Minimizes manual handling, reducing the risk of injuries caused by repetitive lifting or awkward cleaning positions.

•

Customizable Designs: Can be tailored to specific industry requirements, with features like modular configurations or compatibility with various cleaning systems.

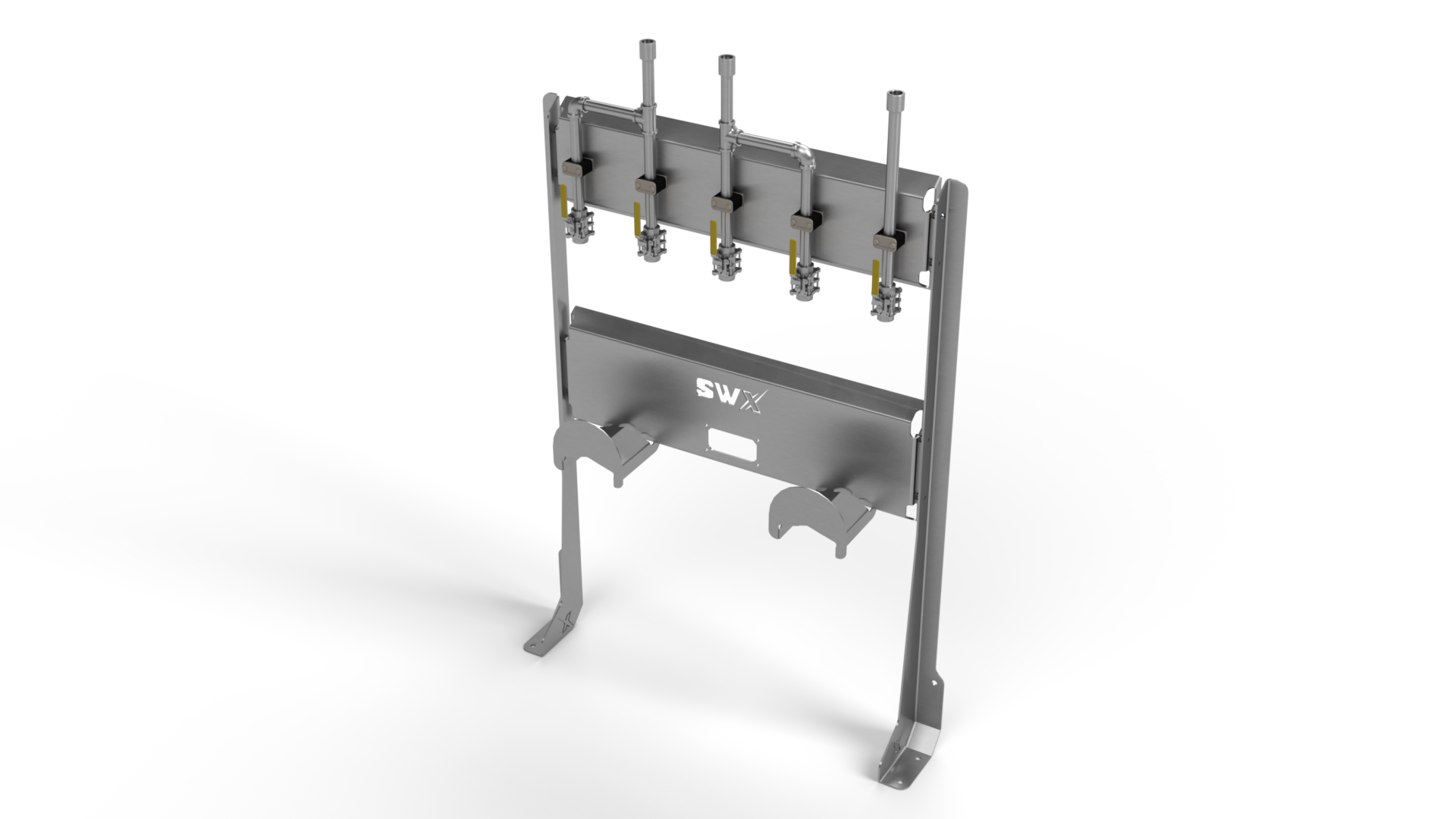

5 Valve Sanitation Station

Food Safety & Benefits

- Versatile Applications: Used for cleaning, cooling, and dispensing fluids like water, chemicals, or lubricants in manufacturing.

- Key Roles: Maintains hygiene, regulates machinery temperatures, and ensures safe handling of fluids.

- Industries Served: Common in food processing, pharmaceuticals, and chemical manufacturing.

- Efficiency Boost: Provides on-demand fluid access, reducing downtime and improving workflow.

- Waste Reduction: Precise fluid delivery minimizes waste, lowering operational costs.

- Enhanced Safety: Robust designs handle high-pressure and hazardous environments safely.

- Customizable Features: Options like temperature control and mixing valves for specific needs.

- Space-Saving Design: Compact configurations optimize facility layout.

- Regulatory Compliance:

Meets hygiene and safety standards critical in industrial settings.

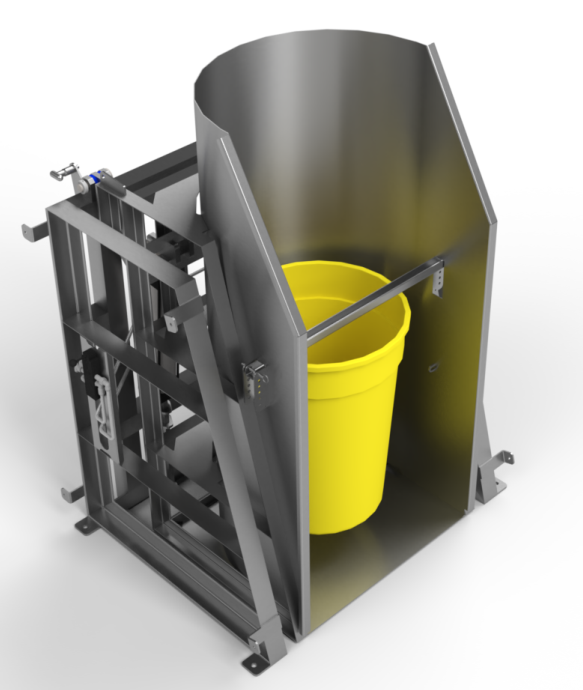

Dumper

Food Safety & Benefits

· Versatile Applications: Barrel dumpers are used for transferring liquids, powders, granules, or solid objects from drums into hoppers, conveyors, or processing equipment, ensuring seamless material handling in diverse settings.

· Key Roles: Enhance material transfer efficiency, minimize spills, maintain product integrity, and support precision in mixing, blending, or disposal tasks.

· Industries Served: Widely utilized in food processing, pharmaceutical manufacturing, chemical production, waste management, and other industries requiring efficient drum handling.

· Efficiency Boost: Streamlines operations by automating drum-emptying processes, reducing labor needs, and minimizing downtime.

· Safety and Ergonomics: Reduces risks of worker injuries by eliminating the need for manual lifting, tilting, and handling of heavy barrels.

· Durability: Constructed with robust materials to withstand heavy-duty use, ensuring long-term reliability in industrial environments.

· Controlled Operation: Allows precise control of dumping speed and angle, preventing product wastage, spills, or damage.

· Customizable Designs: Adaptable to various drum sizes, materials, and operational requirements, with options for adjustable heights, tilting angles, and compatibility with automated systems.

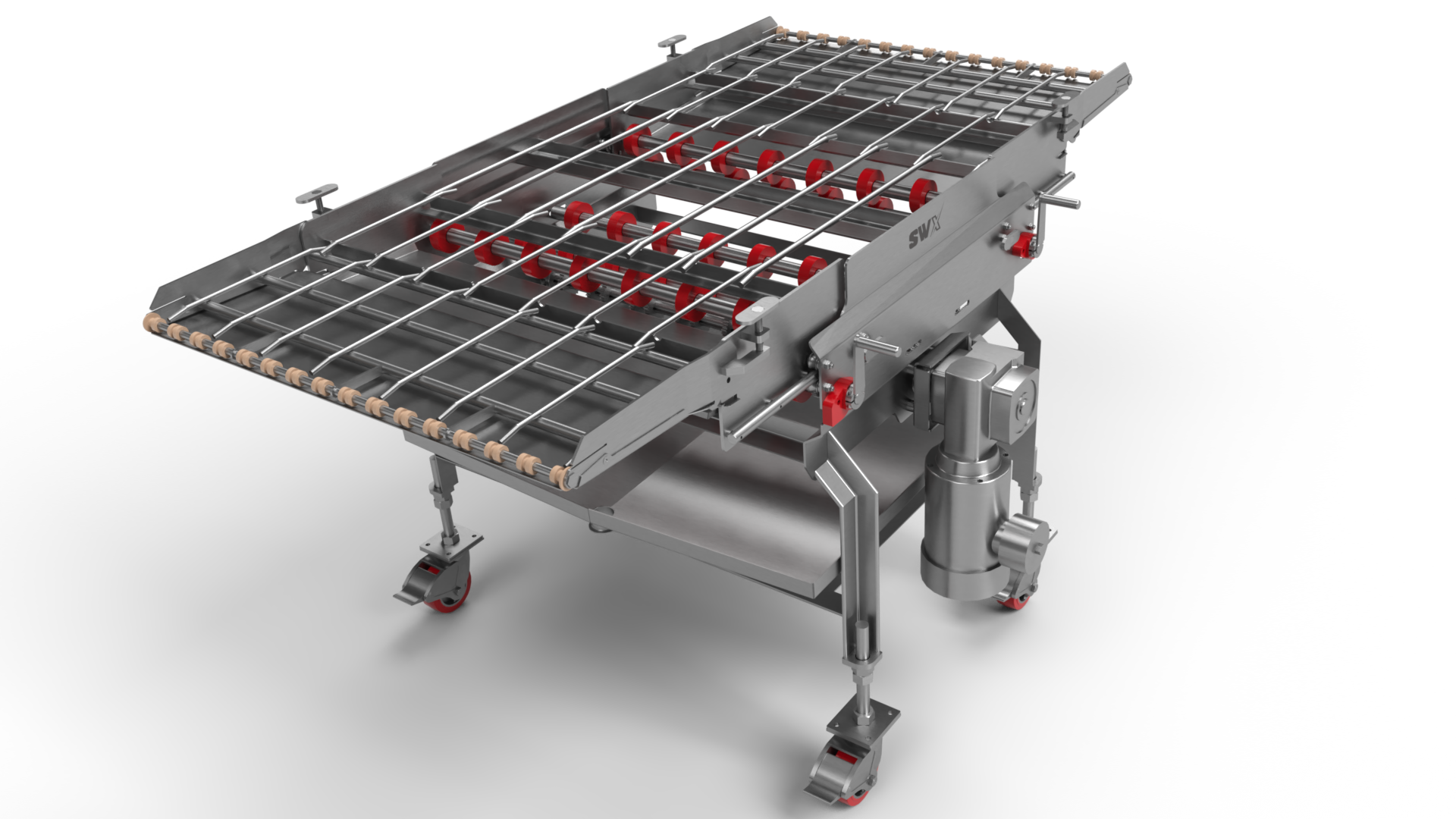

Extendable Wirebelt

Food Safety & Benefits

· Versatile Applications: Wire belt conveyors are used for transporting a wide range of materials, including food products, metal parts, and heavy industrial goods, ensuring efficient movement in various manufacturing, processing, and packaging environments.

· Key Roles: Improve material handling efficiency, facilitate processes like baking, cooling, and drying, support product integrity, and ensure smooth transitions between production stages.

· Industries Served: Commonly used in food processing, metalworking, packaging, automotive assembly, electronics, and industries with harsh environmental conditions requiring durable conveyor systems.

· Efficiency Boost: Enhances production flow by providing continuous material movement, reducing bottlenecks, and minimizing downtime due to the high strength and reliability of the wire belt.

· Safety and Ergonomics: Reduces worker strain by automating the transfer of heavy or hot items, preventing manual lifting or handling of potentially dangerous materials.

· Durability: Constructed from robust materials like stainless steel, these conveyors offer long-term performance, even under extreme conditions like high temperatures, corrosion, or exposure to heavy loads.

· Controlled Operation: Allows precise control over material movement, ideal for applications that require careful handling of delicate or temperature-sensitive products, minimizing waste and damage.

· Customizable Designs:

Can be tailored to fit specific operational needs, with options for mesh size, belt width, material composition, and adaptability to varying temperatures and load capacities.

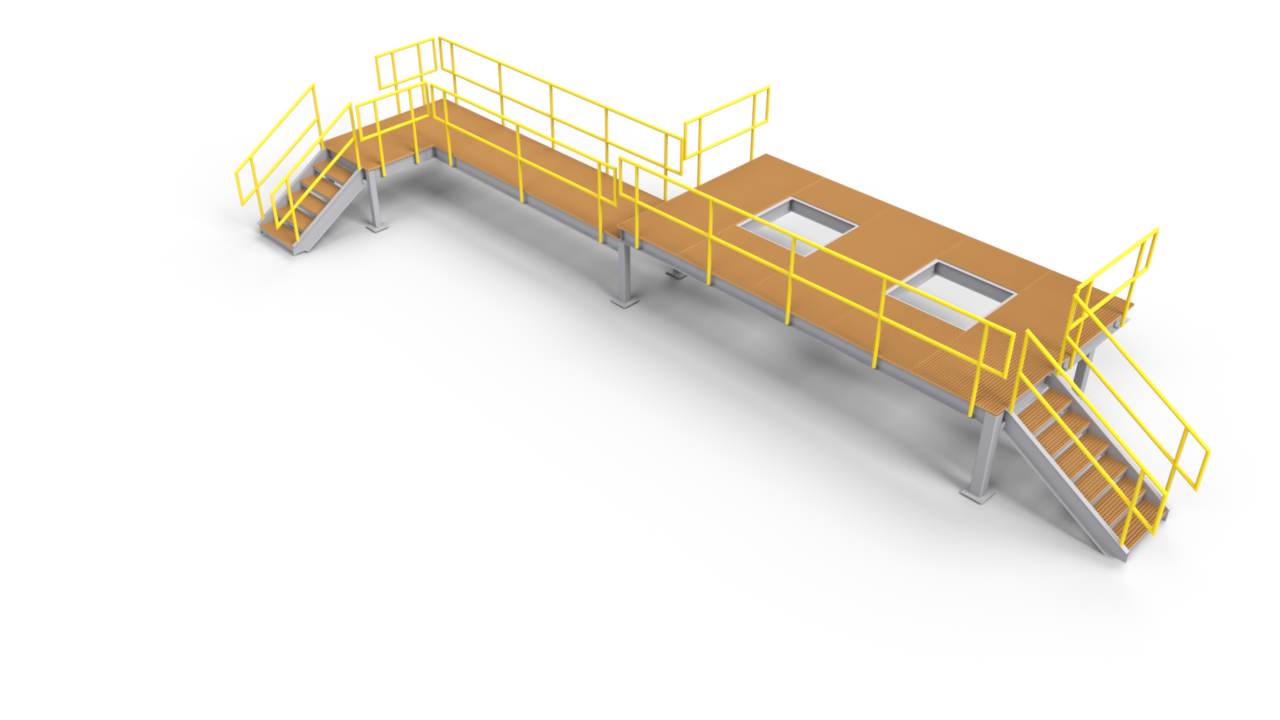

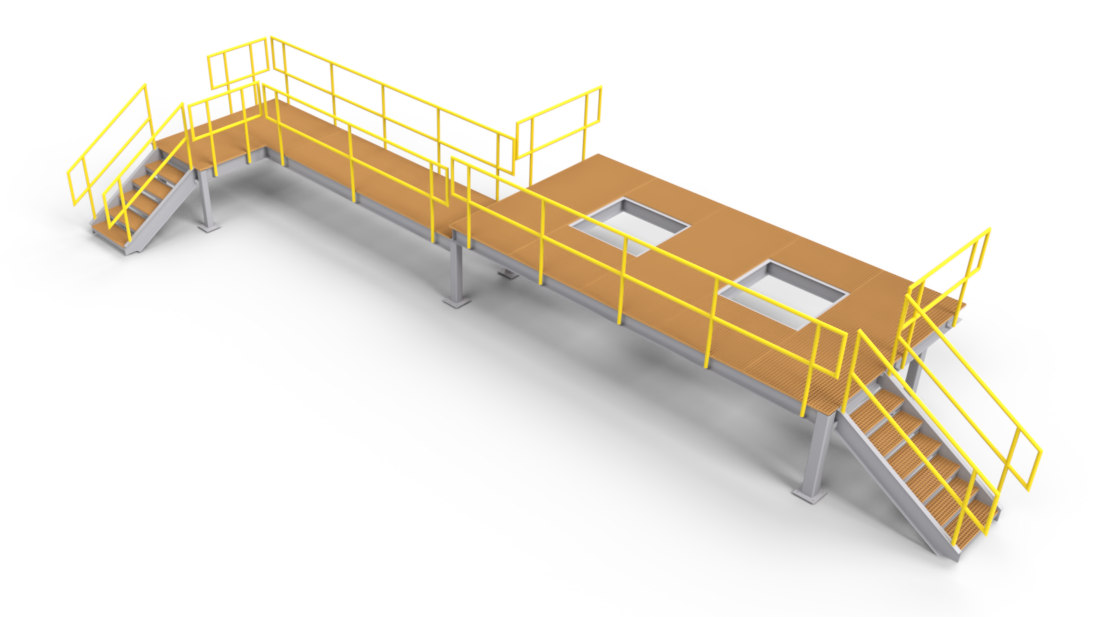

Platforms

Food Safety & Benefits

· Versatile Applications: Platforms are used for accessing elevated areas, supporting conveyor systems, organizing materials, and performing assemby, inspection, and cleaning tasks.

· Key Roles: Enhance workflow by improving safety, optimizing space, and providing ergonomic access to machinery and workstations.

· Industries Served: Common in manufacturing, food processing, warehousing, and maintenance operations.

· Efficiency Boost: Streamlines operations by reducing manual labor, increasing productivity, and minimizing downtime during maintenance and cleaning.

· Space Optimization: Maximizes vertical space usage, creating additional storage or operational areas without expanding the facility footprint.

· Durability: Constructed with robust, often food-grade materials like stainless steel for long-term use and easy maintenance.

· Hygiene and Compliance: In the food industry, platforms meet strict regulatory standards for cleanliness, safety, and sanitation.

· Safety Features: Provide secure access to elevated areas, reducing the risk of workplace injuries and improving ergonomic conditions.

· Customizable Design: Offer tailored solutions for specific industry needs, such as modular configurations or adjustable heights.